With the popularization of automation technology, industrial robots are increasingly applied in enterprises, among which welding, as the main application of industrial robots, accounts for more than 50% in the market. Many enterprises will install welding seam tracking systems on robots to improve welding efficiency. However, many friends who are new to welding robots do not know the role of welding seam tracking systems and why they need to be installed.

Today, let's learn about the role of welding seam tracking systems together.

Teaching and Reproduction

Before studying the role of welding seam tracking systems, we need to first understand the basic working principle of industrial robots, "teaching and reproduction". Teaching, also known as guidance, is guided by the user to guide the robot to perform the actual task step by step. During the guidance process, the robot automatically remembers the position, attitude, motion parameters, process parameters, etc. of each action in teaching and generates a program that executes all operations continuously. After completing the teaching, just give the robot a start command, and the robot will perform all operations accurately in accordance with the teaching actions, step by step. This is teaching and reproduction. Simply put, tell the robot where the starting point and end point of the workpiece to be welded are, so that the welding trajectory can be generated based on the teaching points to carry out the work.

However, this trajectory is fixed. If in real production, the workpiece deviates due to pairing, placement, or clamping, and the actual position of the workpiece is inconsistent with the teaching position, the robot is not aware of it and will still weld according to the teaching trajectory, which will cause problems such as miswelding and leakage welding, seriously affecting welding quality and production efficiency.

Welding Seam Tracking System

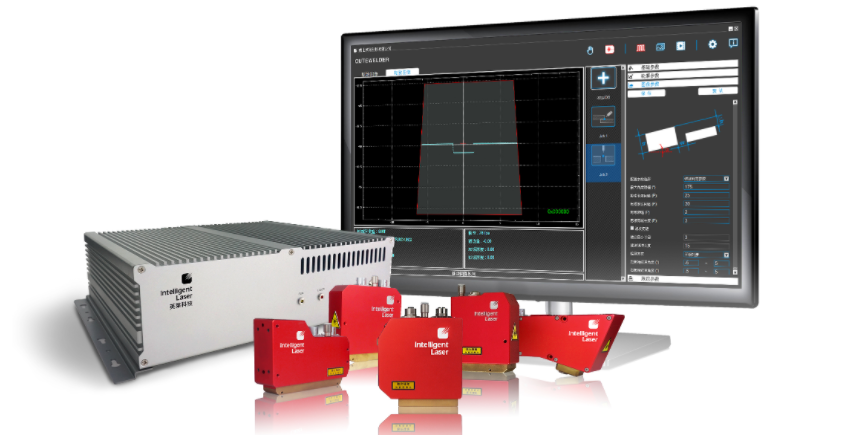

After the welding robot is equipped with a welding seam tracking system, the laser vision sensor installed at the front end of the robot welding gun can actively collect welding seam information through optical measurement algorithms, complete information processing quickly through the control host, and feedback to the robot or welding specialized machine to autonomously correct the teaching trajectory, realizing real-time tracking of the welding seam and achieving high-quality welding. It is equivalent to giving the robot "eyes" to "see" the welding seam.

Can effectively solve the following pain points:

● Poor consistency of workpiece welding seams, requiring repeated teaching

● Need to strictly control the processing accuracy of the previous process

● Welding process requires the use of large and complex fixtures for positioning

● Workpieces deform due to heat

The laser vision welding seam tracking system, as an important component of the welding automation control system, can guide the robot to identify welding seam information, correct deviation, teach a single time for the same workpiece and achieve continuous production, improve welding quality, and improve production efficiency. It has become one of the core components of automatic welding.