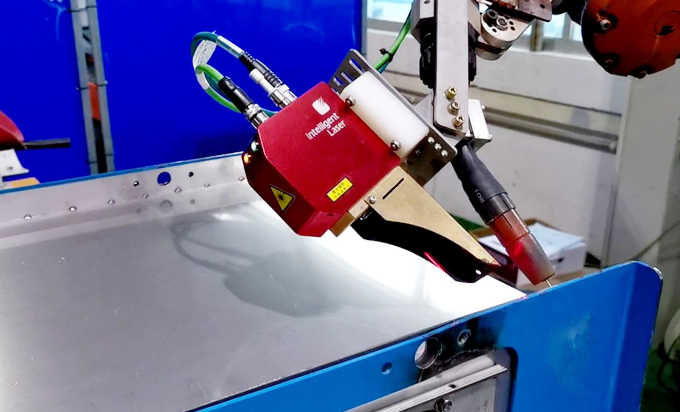

Require help with seam tracking sensors for mechanised welding but do not know where to start from? You have come to the right place! This blog will give you an extensive beginner's guide to help you learn the key characteristics of a high quality seam tracking sensor and when you should buy. Faultless welding needs accuracy and perfect guidance, and seam tracking sensors are means to achieve that. We’ll examine the leading features of high tech laser seam tracking welding in this post.

Pinpoint

Consistency

Portability

Easy to operate

The only thing that counts when looking for the quality of an effective laser vision systems is pinpoint. When it comes to traditional welding procedures, they always depend on excess material to hope that the robot will “come across” the desired seam, quite by luck. By contrast, a high-quality seam tracking sensor makes sure the perfect position, placing the weld at the just right position where required. The accuracy you get from is such that you will reduce expenses and scrap and increase the use of resources.

The most essential consideration in choosing seam tracking sensors is dependability. Welding environments are extremely difficult owing to extreme temperatures, dust, and moisture. All of them can have an impact on the sensor’s performance. Therefore, a robust seam tracking sensor should be in a position to survive in these testing conditions.

Seek features like:

Gas and liquid cooling systems for effective temperature maintenance

Supplemental cooling parts to lower ambient air temperature

These ideas help in dependable accuracy even in the most demanding welding conditions, reducing downtime and providing permanent operation.

The ultimate product to choose should have versatility in a seam tracking sensor, which will allow it to be used across different welding uses. This flexibility is especially significant for system integrators, because they eliminate the need to learn more than one set of beliefs about sensor technology.

The use of a single dependable sensor means:

Simplified system arrangement

Satisfying the different customer’s standards

Handling niche situations without needing to purchase specific systems

This kind of adaptability presents associability with changing requirements whereby you don’t have to develop any application sensor, creating response as well as significant projects.

Judicious use of simplicity and customization, both have the fight of play. The good quality UHIs doe the job well by providing the right parameters without frustrating the user.

Main features are:

Easy to learn security mechanism

Visible posting of shared information depending on special requested items

Limited or no training necessary

The ease of having others benefit from adaptability helps:

Seamless adaptation to various applications

Efficient welding cell modifications

Quick adjustments to accommodate new components

Latest Blogs

How do I Choose the Right Seam Tracking Sensor?

This guide helps you understand the key characteristics of high-quality seam tracking sensors and when you should buy one. Perfect welding requires precision and accurate guidance, and weld seam tracking sensors are the tools to achieve this.

Yinglai Technology Successfully Recognized as a National-Level "Little Giant" Enterprise

On October 20th, the Department of Industry and Information Technology of Hebei Province officially announced the list of Specialized and Innovative “Little Giant” enterprises in 2025, and Yinglai Tech was honored to be included!

What Can Happen During Laser Welding? The Hidden Risks and Sensor-Based Solutions

Misalignment is a common problem in laser welding. Components may not fit together correctly, leading to weak welds. A Laser Vision System helps monitor alignment during the process, providing real-time adjustments.

Let Us Provide a Professional Solution for You Today

Our experienced team can provide customized service to all kinds of projects. Also, we provide 24/7 aftersale service.

Our aim is to make sure all customer can use the laser sensor after receiving it instead of put it in the box.